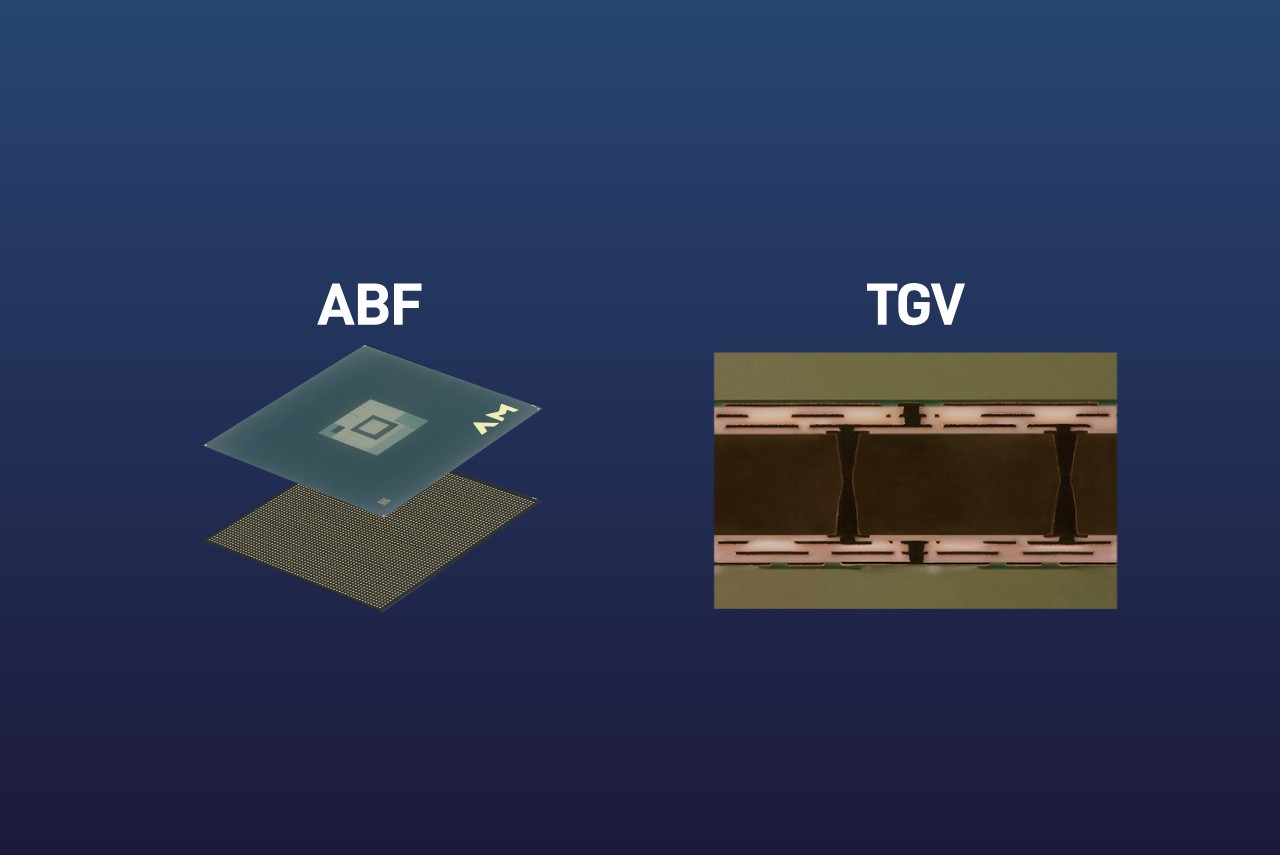

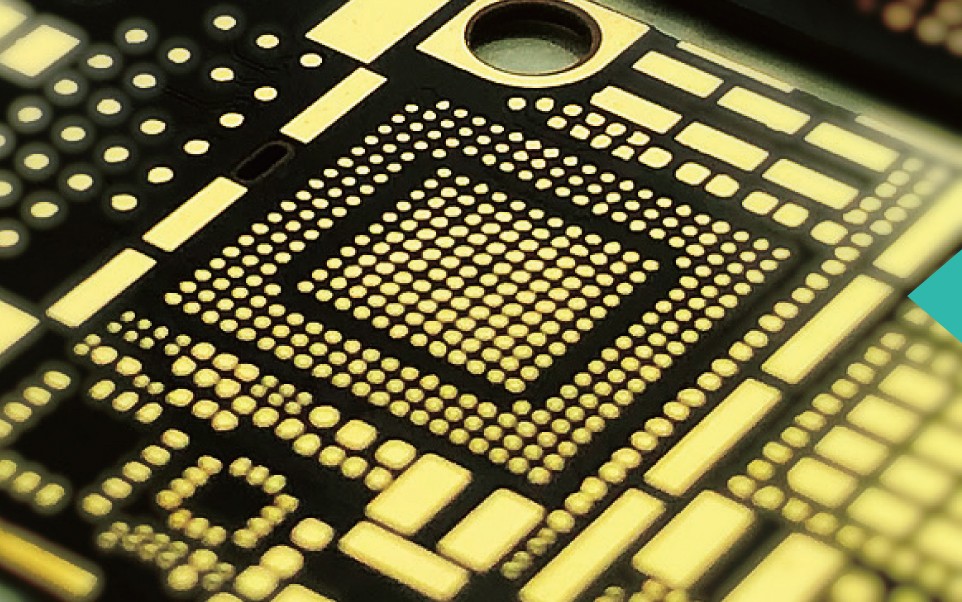

ABF & TGV Substrate

ABF & TGV Substrate

ABF Substrate

- Body Size Max. 110 x 110mm

- Stackup Max.10+N+10

- Bulidup Layer Via/Pad Size (um) Min.50/75

- Bulidup Layer Line/Space (um) Min.8/8

- Bump Ptich (um) Min.90

TGV Substrate

- Sample build for 8+2+8 and above in Xiamen

- TGV diameter 100um and below

BT Substrate

BT Substrate

- 14L Anylayer with core / coreless structure

- Line/Spaces:

・Subtractive: 20/25 um

・mSAP: 12/18 um

・ETS: 12/12 um sample - 130um Pitch Flip-Chip CSP/BGA

- Sub-0.2mm 6L Core/Coreless substrates

- BT/FR5 Ultra low CTE, Low loss materials

- 2.5D cavity, Embedded pattern (ETS:Embedded Trace Substrates), Distributive buried capacitance and buried resistance layer

- Solder-on-Pad (SOP Technology within print and microball)

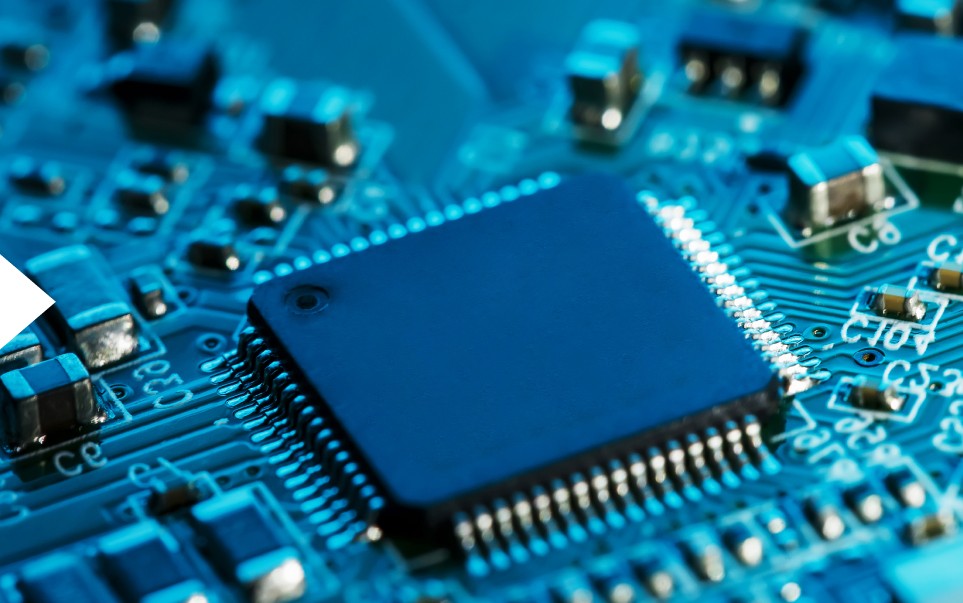

Advanced HDI PCBs

Advanced HDI PCBs

High volume, reliable advanced HDI products

with up to 16 layer any layer

40/40um L/S

Fine pitch BGA

Up to 77G Hz High speed material hybrid HDI

Heavy Cu, Coin and novel thermal solutions

Substrate-Like-PCB(SLP)

Substrate-Like-PCB(SLP)

- 16L Anylayer

- 110um (Coreless) Min. Board Thickness

- 18/22 um L/S with mSAP

- Min. Flip Chip Pitch 127 um

- Next generation mainboard solutions for fine pitch, large I/O counts packages on mobile devices

- Cavity and 2.5D structures

SLP (Substrate-like-PCB) PCBs

SLP (Substrate-like-PCB) PCBs

High volume, reliable substrate-like-PCB

(SLP) products with Modified Semi-Additive (mSAP) technology

30/30um L/S

Fine pitch Fan-out Wafer

Level Package with large I/OS

Advanced & Anylayer HDI & Rigid-Flex

Advanced & Anylayer HDI & Rigid-Flex

HDI

- Up to 18L Anylayer HDI

- 30 /30 um L/S

- 0.3mm fine-pitch BGA

- Up to 77GHz high speed material hybrid HDI

- Cavity and 2.5D structures

Rigid – Flex

- Conventional PTH and Advanced/Anylayer HDl for Rigid-Flex PCBs w up to 10 flex layers

- 25 /25 um L/S

- 12um Pl, 10um coverlay ultra thin Rigid-Flex

- Pl and low loss mPl / LCP materials

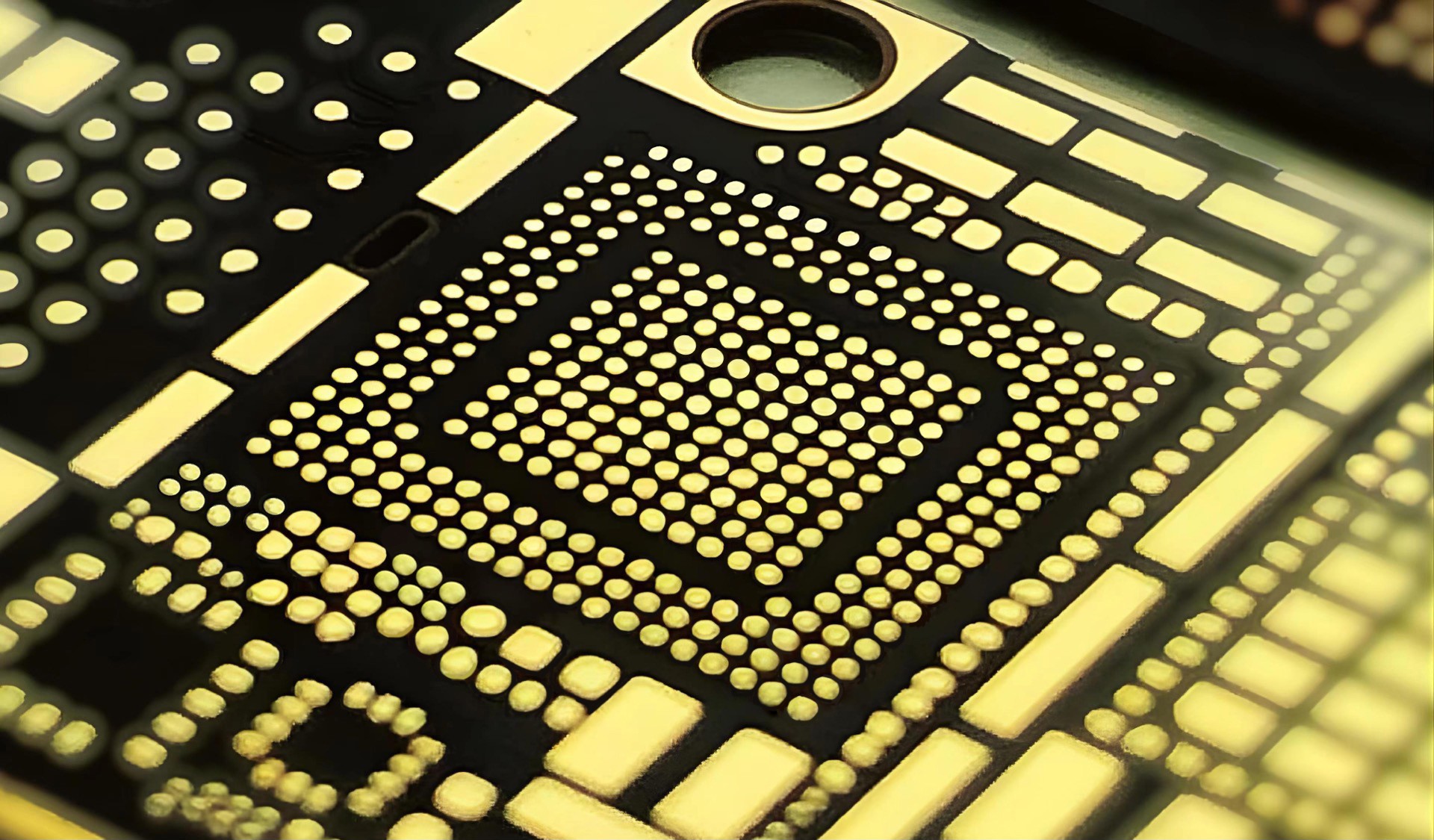

IC Substrates

IC Substrates

Ultra thin, highly customized module substrates

20/40um Subtractive, 20/30um mSAP L/S

150um Pitch Flip-chip CSP

<0.2mm 6L Core/Coreless substrate

BT/FR5 Ultra low CTE, Low loss, LED module Application Material

2.5D Cavity, Embedded Pattern, Distributive buried capacitance and buried resistance layer

Solder-on-Pad (SOP Technology)

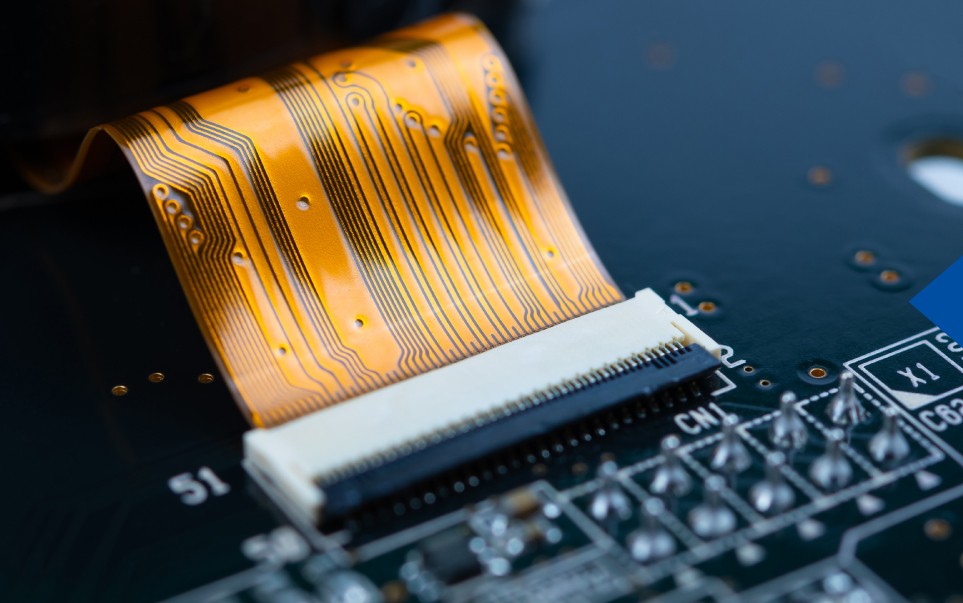

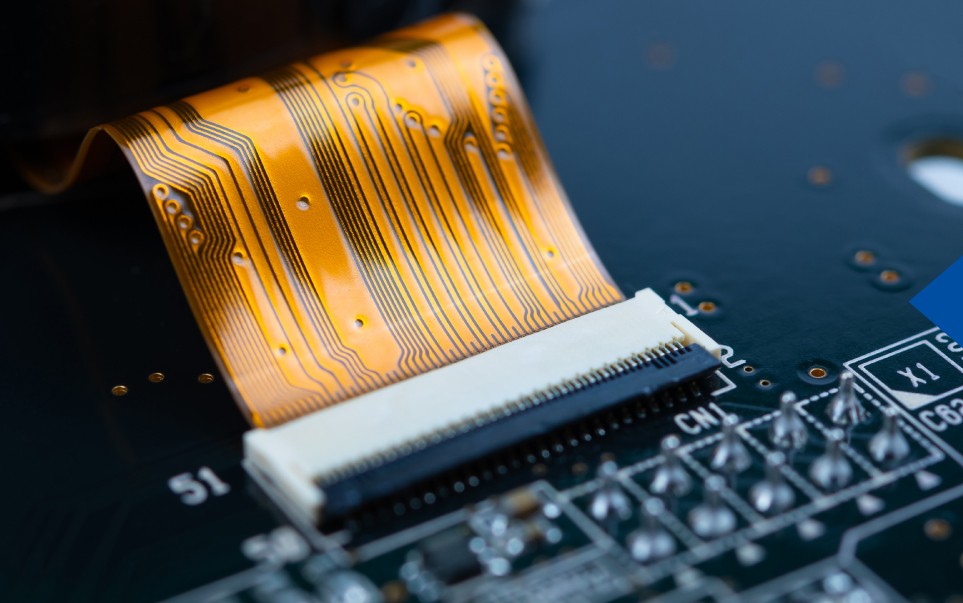

Flex & Assembly

Flex & Assembly

- 30 / 30 um L/S

- FPC Overall Board Thickness :0.036-0.8 mm

- 0.3 mm PIN Pitch (Connector & IC Chip)

- 0.35mm Pitch BGA/CSP/Flip chip

- PI and low loss mPI / LCP materials

- Flex-to-Install / Dynamic bend / Semi-Flex(Bending FR4 Flex)

- Symmetrical / Asymmetrical structures

- Component: 01005

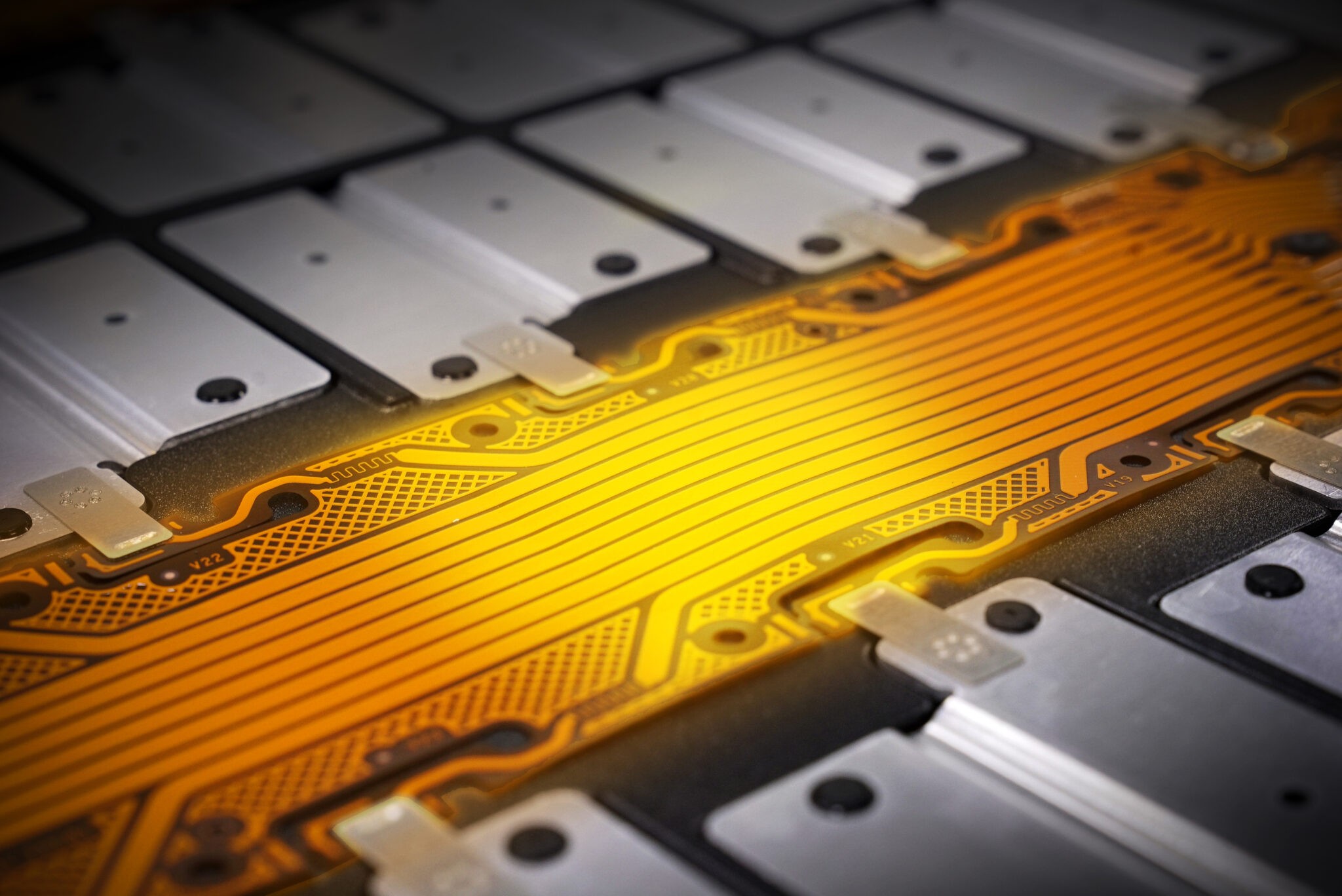

Power Battery Module (CCS)

Power Battery Module (CCS)

- Large panel size up to 2.4m for FPC and 2m for FPCA for temperature and voltage sensing and overcurrent protection

- Puncture crimp connector, Al/Cu ultrasonic welding

- PET insulation film lamination CCS, Hot riveting & injection molding CCS

- One stop-shop for design development, layout, simulation, fabrication, SMT, testing and assembly

Flex / Flex-assembly / Rigid Flexible (HDI) PCBs

Flex / Flex-assembly / Rigid Flexible (HDI) PCBs

Flex, Flex-assembly, Rigid-flex

with advanced HDI / any layer technology

40/40um L/S

Fine pitch devices

12um PI, 10um Coverlay ultra thin thickness

Dynamic bend / Install bend / Semi-Flex

Symetrical/Unsymmetrical structures

PI and low loss PI/LCP materials

Customized assembly and testing